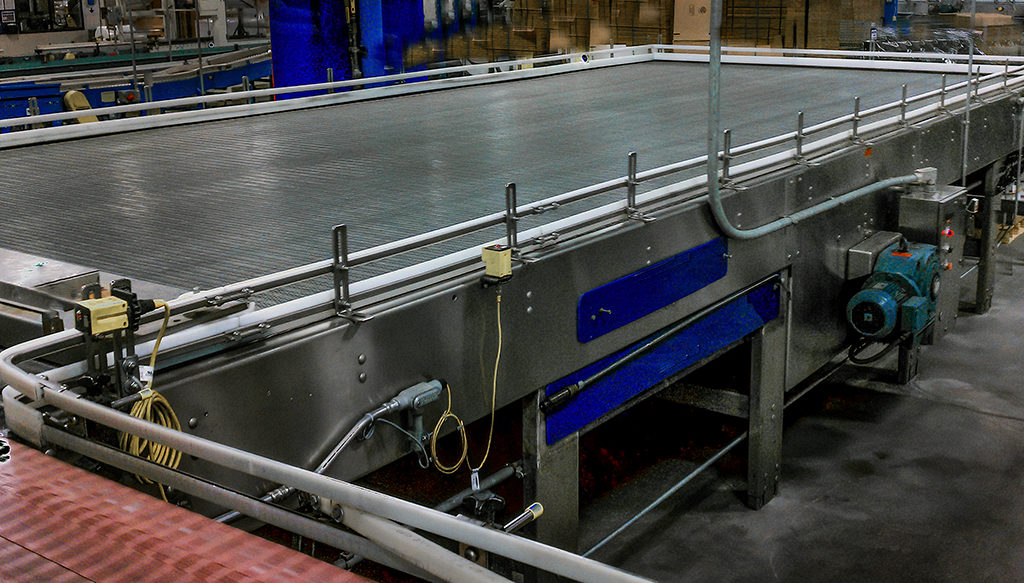

MatTop Plastic Belt Conveyors

Belt conveyors are the most versatile of the product conveyors. Used primarily for both products and their primary packaging. Widely used for food in stainless steel, for washdown or sanitary requirements.

Its modular linked segments allow for easy cleaning and maintenance. Well suited for product accumulation, high speeds, temperature resistance, and durability.

Belt conveyors have many different belt patterns available in widths from 3″ to 120″. They are available in friction tops for use in inclines, declines, and special handling requirements.

TableTop Chain Conveyors

Available in stainless steel or mild steel construction. Tabletop chain conveyors are widely used for can and bottle conveying and accumulation tables in the beverage industry. They work well for side transfers from lane to lane when flush-mounted, which makes them very adaptable for diverse layouts.

Chain conveyors are great for inclines, declines, level straights, and small radius curves. It’s available in widths from 3-1/4″ to 15″.

Cable Conveyors

Intended for use in handling a variety of empty and full containers to and from primary packaging. It’s available in mild steel, stainless steel, and aluminum construction. Cable Conveyors use plastic covered steel cables for moving containers with underside contact.

Intermediate conveyor lengths are 100’, and long conveyors up to 300’.

These conveyors are powered with single groove drives for empty containers and double groove for full containers. It’s available in a number of drive, take-up, and idler combinations.

Other Product Conveyors

We can provide many other styles of special-purpose product conveyors for particular applications. These include other belt conveyors such as sanitary fabric belt, trough belt, mini-belt, single or multi-strand plastic chain, vertical “alpines”, ARB (activated roller belt), special hand pack station conveyors, etc.

Welcome OEM partners. We help OEM’s plan and evaluate the best and most cost-effective conveyor solutions for their clients.